Students branching out into STEM fields

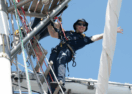

Millie McCarthy, Zach Watts and Chaise Mayson were part of the first intake of Geelong Manufacturing Council's future industry programs. Photo: BILLY HIGGINS

GEELONG secondary school students are getting a taste for the city’s renowned manufacturing sector as a potential career path through an industry-led work placement program.

Geelong Manufacturing Council (GMC) launched a range of industry leadership initiatives, including programs aimed at VET stream students and girls interested in STEM (science, technology, engineering and mathematics) fields, for year nine and 10 students last year.

Rave reviews from participating schools and businesses means another cohort will get involved this year.

The program mixes students from different schools across Geelong and places them for one day a month in a real-life work setting at a local manufacturing business, where they can talk to leaders and role models about potential career options and take part in practical workshops that use specialised equipment.

Activities part of the program in year one included making solar-powered windmills, designing a mini-golf course and metal casting a “foundry in a box”.

Millie McCarthy, who joined the program as a year nine Sacred Heart College student, said it had provided more clarity about potential career options.

“We experienced all these different types of fields we could go into and we could look to for pathways.

That was really helpful to me to know what kind of subjects I wanted to do,” she said.

Geelong Lutheran College student Zach Watts said he had highly recommended the program to his school mates.

“I’m kind of the stereotypical high school student; I had no idea and still don’t know what I want to do.

“To get first-hand knowledge about industries like manufacturing and engineering and STEM, that’s the best way to find out.

“You can just get thrown straight into it and get to see everything, not just one specific area.”

Oberon High School’s Chaise Mayson said the diversity of GMC’s programs was rewarding.

“You went to places like Godfrey Hirst, looking at carpet or Austeng doing engineering; they were completely different branches of companies, but are still involved in the same sort of field.”

Godfrey Hirst manufacturing manager Aaron Dawson said the program had benefits for the carpet maker’s employees too, and that his business would reap the rewards of a robust local manufacturing industry that the program aimed to support.

“Being here for so long, it’s important for us to give back to the community and try and help where we can.

“Especially in programs like this that help get more kids, and especially girls into engineering.

“Our employees that were exposed to it had heaps of praise for the students that were coming in and doing hands-on work – they were keen to get involved and roll up the sleeves.”